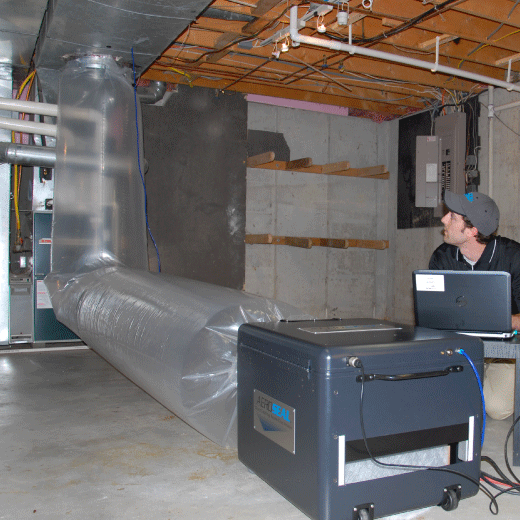

Duct Blaster HVAC Leak Testing

A blower door is an innovative diagnostic tool used in energy audits to measure a building's airtightness. By simulating pressure differences, it helps detect and quantify air leaks, enabling precise identification and sealing of areas that compromise energy efficiency and indoor comfort.

Learn MoreDuct Leak Sealing

When combined with a blower door, an infrared scan is a powerful duo in energy auditing. The blower door pressurizes or depressurizes the building to reveal air leaks, while the infrared scan visually highlights temperature differences, making it easy to pinpoint energy-wasting gaps in the building envelope.

Additional Pressure Pan Testing

During a blower door test, a pressure pan is positioned over supply and return vents to measure air pressure differentials, enabling the evaluation of heat or cooling loss and the identification of potential airflow issues or leaks within specific duct runs. *There is an additional cost to perform this test during a blower door.

Sealing With Duct Seal Mastic

Duct Sealing With Mastic

Sealing HVAC duct system leaks with a traditional approach involves the meticulous application of metal tape and mastic, providing a robust solution to enhance energy efficiency and indoor air quality. Metal tape, with its durable adhesive properties, is employed to secure joints and seams, preventing the escape of conditioned air. Mastic, a thick and flexible sealant, is then skillfully applied over the tape to create a lasting barrier against leaks. This method is particularly effective for flex ductwork, offering a versatile solution that conforms seamlessly to the contours of the ducts. By addressing leaks through this comprehensive approach, not only is energy waste minimized, but the overall performance of the HVAC system is optimized, resulting in a more comfortable and cost-effective home environment.

Sealing With AeroSeal Duct Sealant

Duct Sealing From The Inside With Aeroseal

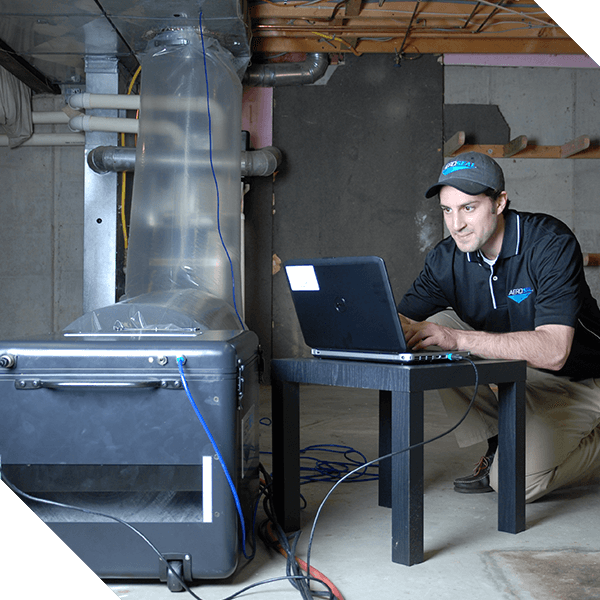

Sealing HVAC duct system leaks from the inside with Aeroseal presents a cutting-edge solution for enhancing energy efficiency and indoor air quality. This revolutionary method is not only effective for traditional ductwork but also proves to be a superb option for sheet metal systems. Aeroseal techn non-toxic, water-based formula effectively seals all the holes in your air ducts and vents, making sure your air goes where you need it – not where you don’t. polymer-based sealant that is injected into the ducts and disperses uniformly, effectively sealing even the tiniest leaks that might be challenging to address through traditional methods. This process not only optimizes the overall performance of the HVAC system by preventing energy wastage but also contributes to a healthier indoor environment by minimizing the infiltration of dust, allergens, and pollutants. It's a cost-effective and convenient approach to ensure that your ductwork operates at peak efficiency, delivering comfort and air quality benefits for your home or business.

Duct Blaster Testing

Ensuring the airtightness of your ducts through comprehensive leak testing and subsequent sealing is a crucial aspect of enhancing your home's energy efficiency, comfort, and air quality. Leaky ducts can result in substantial energy loss as conditioned air escapes, forcing your HVAC system to overwork and raising energy expenses. Thorough testing identifies leaky areas, allowing for proactive measures to seal them effectively. By sealing these leaks, you not only cut energy costs but also maintain consistent home comfort, ensuring even distribution of heating and cooling. Moreover, sealing duct leaks blocks the entry of dust, pollutants, and allergens into your HVAC system, significantly enhancing indoor air quality and fostering a healthier living environment. This investment in leak testing and sealing contributes to an efficient and superior ventilation system for your home.

It's worth noting that many HVAC contractors overseeing duct installation may overlook air leak testing on completed projects, and not all contractors consistently ensure proper duct sealing during installation or replacement, underlining the importance of post-installation testing and sealing procedures.

Duct Leak Testing

$250 / per unit

- Duct Blaster Pressure Test

- Duct Leak Inspection

- Duct Condition Inspection

- Report Of Duct Pressure Test

- Pictures Of Problem Areas

- Infrared Test

- Blower Door Testing

- Repairs Not Made

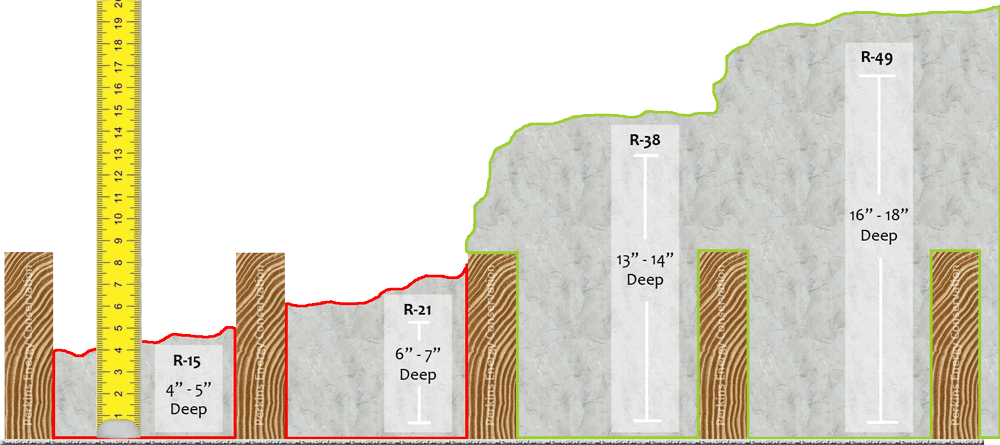

Is Your Attic Costing You Money?!?!

All it takes is a quick peek to find out! Many older homes have more air leaks and less insulation than homes built today. If your attic floor is insulated but the wood beams (joists) are still visible, you probably don’t have enough attic insulation and it wouldn’t be a bad idea to reach out to us today for a free insulation quote!